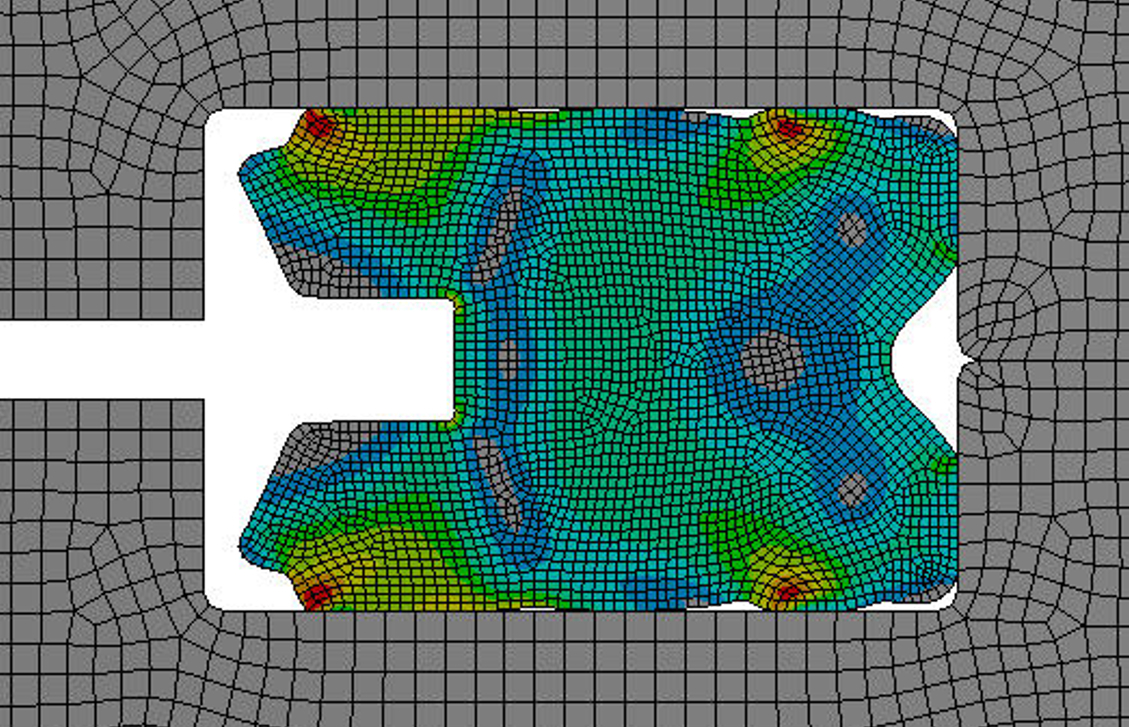

During the development phase our engineers create a customized sealing solution. Our 3D models are a core element in acceleration towards series-production readiness. They are fundamental to our computer supported simulations which offer valuable early insights into the expected functionality of the seal.

In addition to the simulations we recommend to use samples for preliminary tests. This applies especially to complex molded parts. Such early samples are prototypes manufactured by machining or by 3D printing. Their purpose is to allow a prompt physical evaluation of the sealing solution. Depending upon the complexity it can be reasonable to employ multiple samples before reaching a decision on the final geometry of the seal.