Service

- 100% inspection

- Surface treatment

- Individual packaging

- Customised marking

- Special labels

- Specific test reports

Automatic assemblies impose high requirements on a seal. Optimal roundness and flatness are essential for a problem-free automatic feeding. Enhanced friction force characteristics facilitate a smooth separation of the seals during the automatic feeding process and also reduce the necessary assembling force.

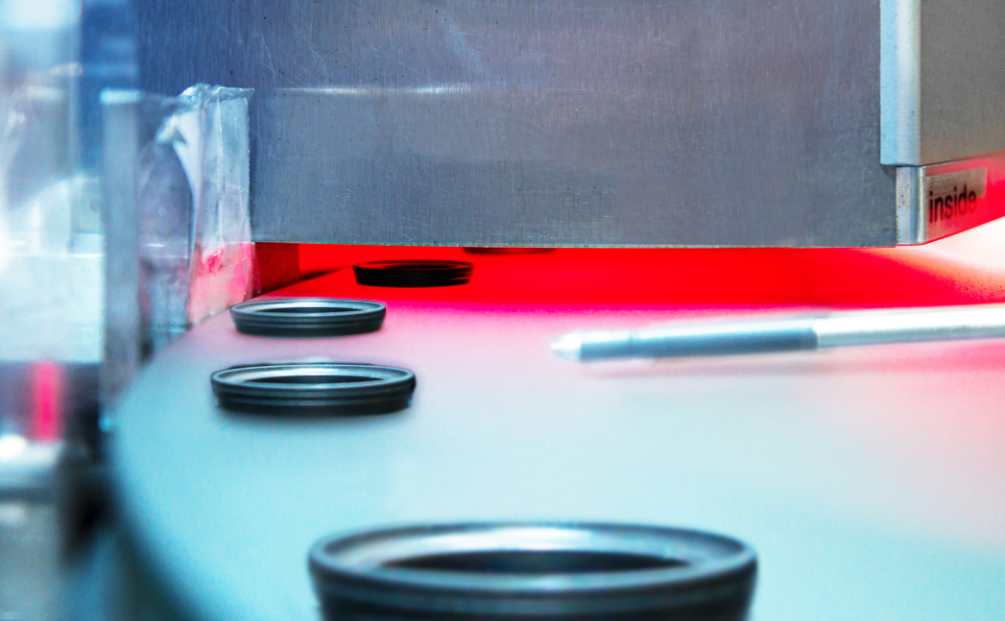

Certain characteristics such as roundness and flatness cannot be guaranteed through process reliability. For these cases we provide 100% inspection. This control can be conducted by machine or by manual labor. Opto-electronical machine control is the first choice for most parts as it also represents the more economical solution. For certain aspects manual control is however indispensable. BodeDynamic is ideally positioned for both control options.

There are various methods for surface treatment in order to improve the friction force characteristics of a sealing element. The simplest option is to apply a coating using lubricants such as oil, grease or graphite. A different approach is to enhance the surface properties by fluorination or plasma activation. The most high end treatment is the application of a dry lubricant coating. We offer a wide range of finishes for different applications and our coatings hold certifications for drinking water as well as for contact with food.

Our service options also include special packaging and individual labels.